Background of the Project

Our client, a manufacturing company, needed to rollout a Manufacturing Execution System (MES) to their biggest manufacturing plant in China. The project involved planning, project-specific requirements engineering, rollout, and coordinating training of users for the MES tool for a smooth production start in two years. This was a huge project, considering the challenges of its sheer size, runtime, and involved parties and machinery.

The Challenge

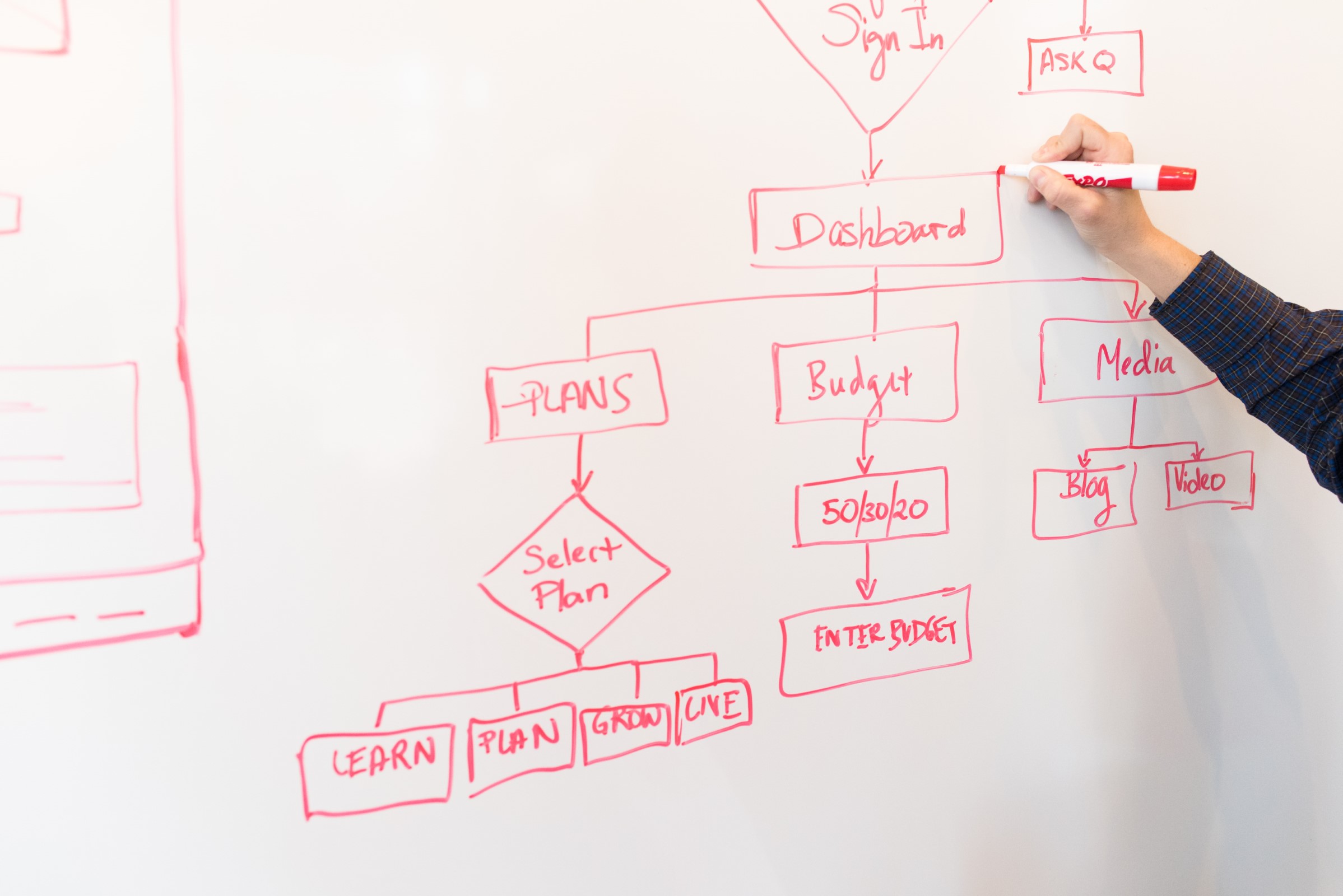

The successful MES rollout required the system to be connected to all machines, different systems like ERP, alarming systems, quality control, part tracking, monitoring solutions, and other components. The project management included requirement eliciting for new features needed for the project and troubleshooting of new development, as it was the client’s biggest construction size to date, with the goal to increase automation and mass production numbers. The project faced challenges such as material shortage, semiconductor supply chain issues, changing and contradicting requirements from different departments, cultural and language barriers, shortage of skilled personnel, and timeline constraints.

The Process

Our consultants worked closely with the client to understand the key challenges and pain points. We identified areas for improvement and helped the client plan and execute the MES rollout successfully. We worked with the client to manage requirements elicitation, new feature development, and troubleshooting, coordinating with different teams and stakeholders. We provided training to users for the MES tool to ensure a smooth production start. We managed on-site visits and worked remotely with a distributed team, overcoming cultural and language barriers.

Results

Our approach led to a successful MES rollout with minimal delay, and the client was able to achieve a smooth production start. The project resulted in several new features for the MES tool, improving automation and increasing mass production numbers. The client also gained new insights and learnings, enhancing their capabilities and positioning in the market.

Conclusion

Rolling out an MES system to a large manufacturing plant in China can be challenging, especially when facing a shortage of skilled personnel, changing requirements, and cultural and language barriers. Our approach, which involved understanding the key challenges and pain points, identifying areas for improvement, and managing requirements elicitation and new feature development, led to a successful MES rollout. The client was able to achieve a smooth production start and enhance their capabilities and positioning in the market.